We’ve all seen the news reports of how Amazon treats its workers like slaves, low wages, impossible work targets, no “loo” breaks, and ending in nervous breakdowns. Could this really be true?

See for Ourselves

I confess I hoped not because the service Amazon gives to its customers, speaking for myself, is exemplary. Prime members can get next day delivery – I’ve often ordered at 10 o’clock at night and received the goods the next afternoon and even ordered in the morning and received the goods the same day. Could all this be based on oppressive “evil” working conditions?

So I was delighted when Rtn. David Holroyd organised a visit the nearest Amazon warehouse, at Dartford, just across the Dartford crossing, for a group of us to see for ourselves. I jumped at the chance and a group of seven of us, including David, Robert, Roger and myself, plus friends, rendezvoused at the Dartford depot on May 29.The depot was not easy to find, despite its enormous size, and we went down a number of wrong turns before we arrived at the correct location, but we we were still a little early for our 1 pm appointment and tour. Not an auspicious start as we were kept waiting in the foyer with minimal seating and no access to WCs until the due time.

An Hour’s Tour

However, right on time our tour guides appeared, and checked us all off against their lists before taking us through into the reception area where there was time for an “comfort break” and we were equipped with walkie talkies with microphones – necessary to hear the tour commentary and to ask questions.

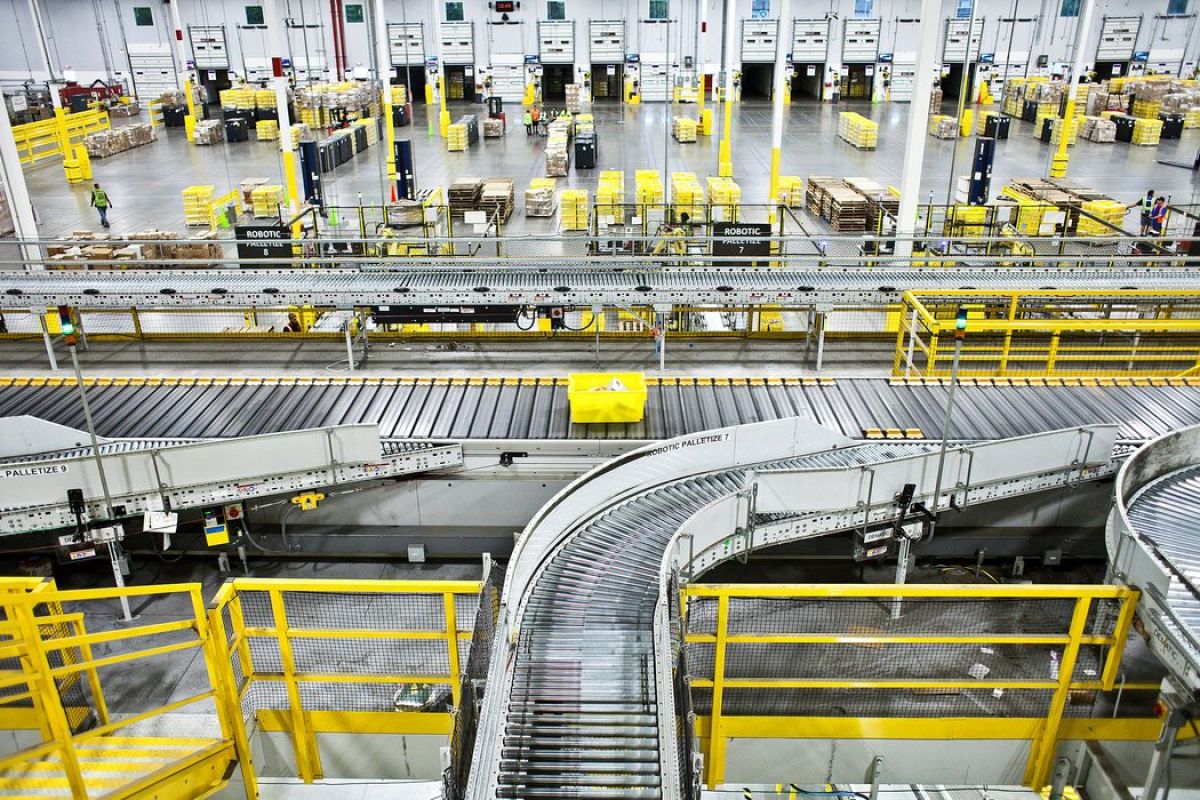

The whole tour took just over an hour and we walked through the length of the warehouse, starting from where the goods actually came in to “Receiving”, were scanned, picked and placed in pods. Each pod was about 6 ft. high and 4-sided with up to 9 rows of up to 4 compartments per row, some small, some larger, to accommodate different size goods.

So Automated

Incoming goods were scanned and a specific compartment in the pod was highlighted to show the operator where to place the product. This way the system always knew where every product was stored – which pod, which side, which row and which compartment.

More importantly, goods were stored randomly so that later in the process, if there were more than one order for a particular product, then multiple operators could pick the same product from different pods at the same time, keeping up the speed of the process. Very efficient, and the pace of the work did not seem that demanding.We went upstairs for the next stage, which was picking, where the system would tell an operator which product to pick from which compartment of a pod and record which fulfilment box it had been placed into. Each pod was on a robot which took its pod to the right station for picking. Very impressive the way a pod was brought to a picking station, avoiding all the other pods, turned the right way to present the right compartment, and a light shone to show from where the part could be picked.

The products then move to packing where the system tells the operator which items to pick and which box/envelope to use, before being “conveyed” to shipping where the package is sealed, address label applied automatically (so the amazon employee never sees who any package is to go to), and the package passed on to the shipping docks to be loaded on the right truck/van. We say the label is applied, but it was fascinating to see the that to avoid damage to a packs contents, the label is actually blown onto the parcel, not stamped on it.

Time to go. A very interesting and enlightening visit.